Unique advantages over low cost FDM printers:

- Fast – up to 10X speed of FDM printers (based on LASER size)

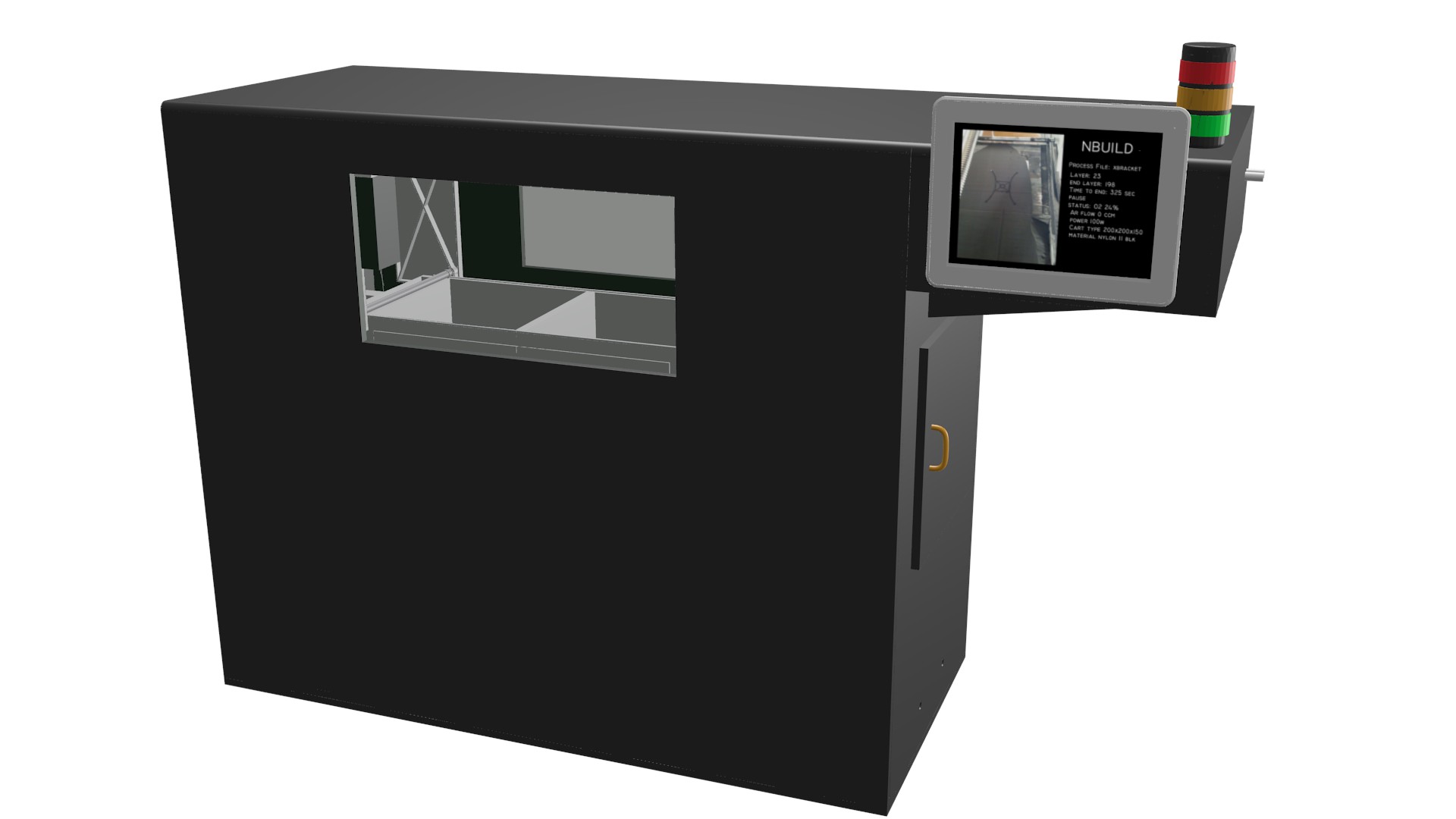

- Cassettes allow rapid switching of materials – cassette holds metal/plastic/composite powder

- Composites up to 8X the strength of polymer alone

- Multiple objects built anywhere in build volume

- Objects can have multiple embedded moving parts

- Thin wireframe structures possible

- No need to add support structures – powder provides support

- Material cost low – bulk powder vs spools

- Higher resolution

- Hollow objects simpler and lower cost – new types of materials with a fine network of thin supports are strong yet lighter than solid – not possible to make any other way

- Material density variable within objects – fabricate flexible or spongy materials embedded along with rigid hard plastics

- Variable density allows many new products to be fabricated that have not been possible before, such as shoes, gloves, billfolds – anywhere more flexible materials need to be embedded in the product

- Parts can have multiple components integrated that are not possible to build in one piece any other way, saving assembly cost

- System can print in metal/plastic/ or composite with switch of cassette

- Input/output cassettes interchangeable

- Output cassette holds built parts in powder

- More cost effective