Specifications:

- Build volume: 190x190x150mm – Model A

- Build volume: 350x190x150mm – Model B

- Laser Power: 100w standard, 200w option

- Layer thickness – programmable, typical 0.1mm

- XY resolution – 50u

- Write speed – plastics to 5000mm/sec w 100w laser – material/laser dependent

- Write speed – metals to 1000mm/sec w 100w laser – material/laser dependent

- Print bed may be heated up to 200C, or unheated for quick prototype turnaround

- Unique dual heating system

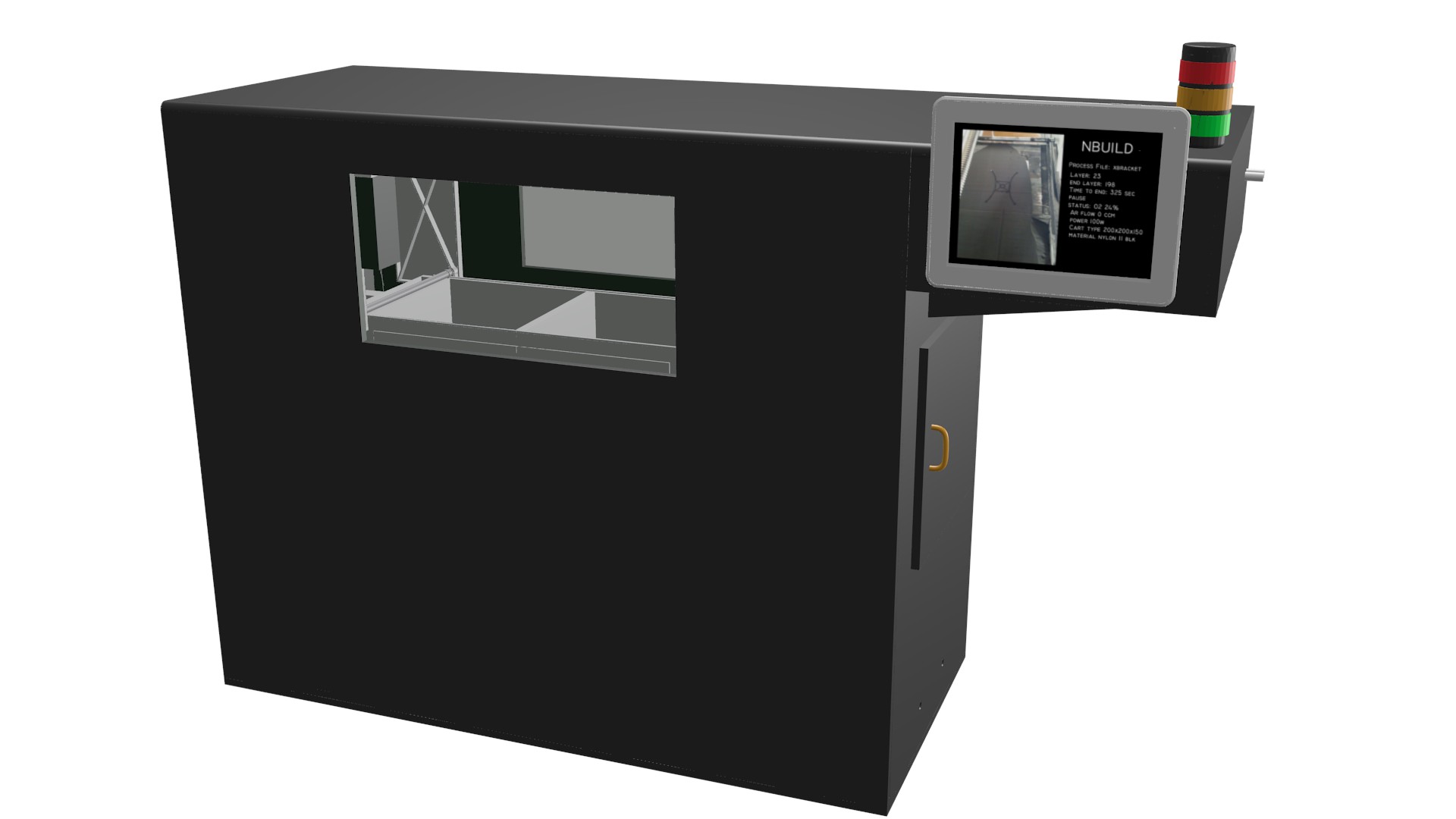

Printer:

- Main chamber dimensions: 900mm(W) x 760mm(H) x 400mm(D)

- Including Electronics shelf: 1300mm(W)

- Empty weight: 25kg

Materials:

Metals:

- S High-grade steels including stainless, Aluminum alloys , Nickel-base alloys, Titanium alloys, Pure titanium , Precious-metal alloys

Polymers:

- Nylon 11, nylon 12, PEEK

Polymer/composites:

- Nylon 11, nylon 12, or PEEK

- Glass or carbon fiber

Ceramics:

- High temperature, various colors.

System:

- Powder loading/unloading with cartridges keeps printer running continuously

- Print bed optional unique dual heating system

- Print bed unheated for maximum print turnaround – no wait for heat/cool cycles

- Wifi connected – all operations controllable via wifi or LAN

- Tablet included – systems come with a Smart Android tablet that operates system through wifi – Tablet is removable

- Remote monitoring – system can be monitored remotely

- Camera inside – build volume area monitored by video camera, remotely viewable

- System can be operated & monitored by smartphone

- Production status indicator option – Tri-color display shows status of printer

- Raspberry Pi – main processor

- 32Gbyte solid state storage

- Slicing done on host computer, printer builds based on slices

- Once printing, printer builds automatically

- Automatic test for inert gas when needed (metals)

- Built for add-on automation – robotic load/unload for mass production environments

- Easy maintenance – cover & sides snap on/off for fast access